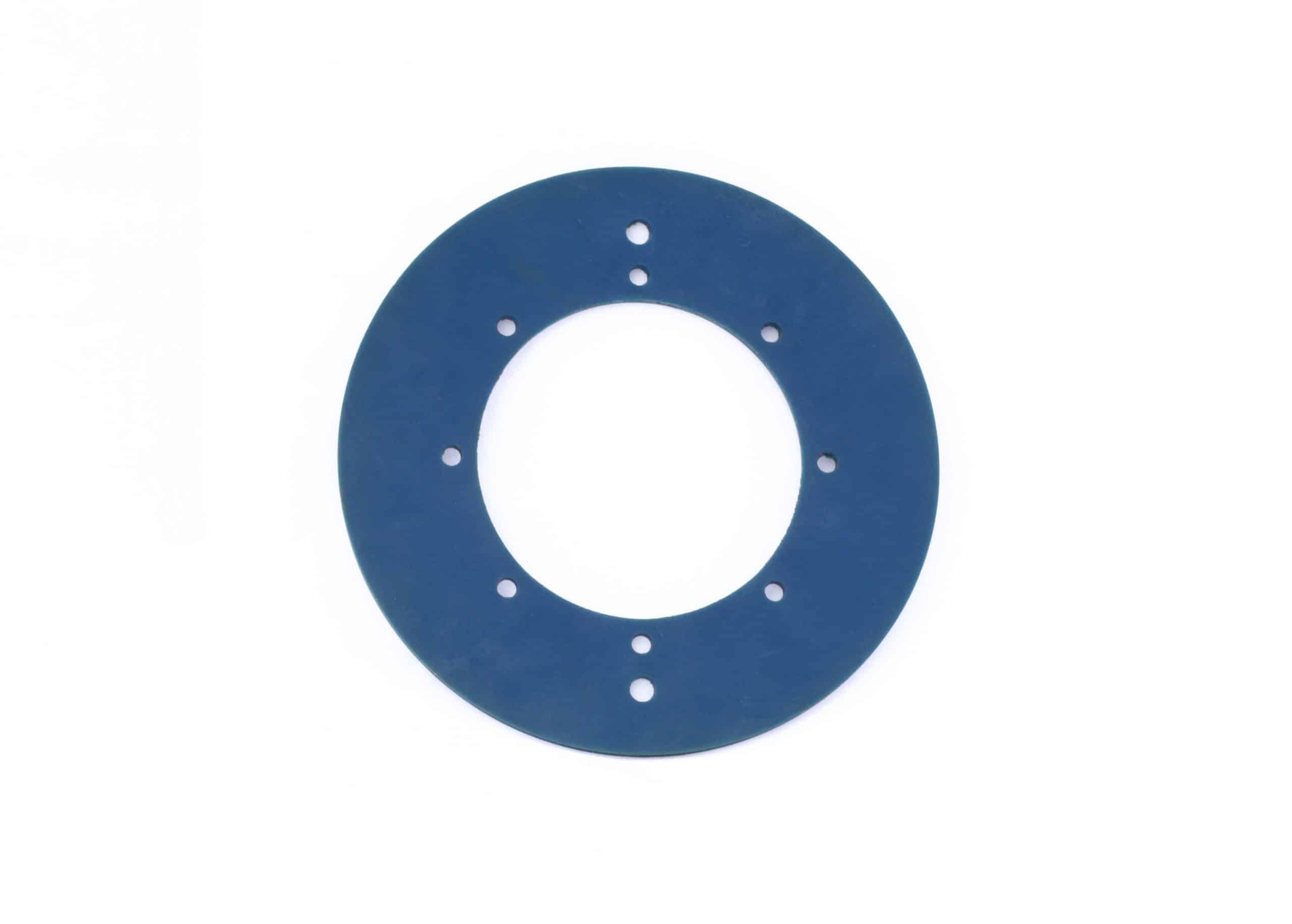

Polyurethane Seals and Gaskets

Uniflex introduces a groundbreaking solution with our Polyurethane Rubber Mold Seals and Gaskets. These innovative alternatives to traditional rubber seals and gaskets offer remarkable durability and similar elastic properties. With superior abrasion resistance, chemical resistance, and rebound capabilities, polyurethane seals and gaskets can effectively replace rubber in demanding situations.

Key Features:

Exceptional Durability: Uniflex’s polyurethane seals and gaskets are built to last. Their impressive abrasion resistance ensures they can withstand the most challenging environments, providing longevity and reliable performance.

Customization: We offer fully customizable urethane seals and gaskets tailored to your exact specifications. Our polyurethane manufacturing process enables us to cast urethane parts with tight tolerances, ensuring a perfect fit and optimal performance.

Application-Specific Solutions: Our extensive selection of molded urethane compounds can be tailored to meet the specific functionality requirements of your applications. Whether you need FDA-approved materials or high-performance Vulkollan® equivalent materials, we’ve got you covered.

Rapid Prototyping: We provide rapid prototyping services, ensuring you have a quick and cost-effective way to test and refine your designs.

Versatile Production: Whether you require low-volume or high-volume production, we have the capabilities to meet your production needs efficiently.

Uniflex’s Custom-Molded Polyurethane Seals and Gaskets offer a transformative solution for demanding applications. Elevate your equipment’s performance and longevity with these durable and customizable alternatives to traditional rubber.

Ready to enhance your equipment’s performance? Explore Uniflex’s Custom-Molded Polyurethane Seals and Gaskets at Uniflex and discover how our innovative polyurethane solutions can revolutionize your operations.

Polyurethane Seals and Gaskets

Our polyurethane seals and gaskets can be molded in accordance with your specific requirements, so send us your drawings or have our team of engineers work with you to design your solution!

Here at Uniflex, we are able to design, machine, and manufacture under one roof, accelerating your project into production. Products can enter production in days!

We offer both high and low volume production runs!

Why polyurethane?

Polyurethane is:

- Resilient

- Durable

- Cost Effective

- Abrasion Resistant

- Impingement Resistant

- Chemical and Oil resistant

- Non-absorptive

- Non-conductive

- Vibration and Shock Dampening

- Extremely Versatile

If you want to learn more about seals and gaskets or would like to request a quote for a custom job, make sure to contact us! We have a staff of experienced engineers ready to answer your questions and help guide you from concept to solution.

More Products

Incredibly useful due to its ability to be molded into a seemingly infinite number of shapes, sizes, and hardness ranges.

We offer high quality, custom rubber compression and transfer molding to produce high quality, economical rubber products that adhere to your specific requirements.

Incredibly useful due to its ability to be molded into a seemingly infinite number of shapes, sizes, and hardness ranges.

We are able to hold the most stringent tolerances that always meet or exceed customer expectations while ensuring an economical price.

We supply more styles and sizes of Kadant Unaflex brand Expansion Joints than any other distributor in the world and offer some of the most competitive pricing available.

Our product line includes molded & pultruded grating, handrail, ladders, structural shapes, stair treads, grating accessories, and FRP doors.

Custom manufactured from our famous non-conductive, ultra-durable UNIDURE© material, our electrical safety devices can be tailored for use in any lockout or tagging situation.

Our press fit cam follower sleeves are designed for ease of use and cost effective/efficient emplacement, while also maintaining exceptionally high quality.

The Uniflex Pipe Coupling has successfully solved frequent leakage, intensive maintenance, and stocking difficulties associated with ground join-pipe unions.