To maintain a seamless supply chain, material handling includes various tools and systems that help with inventory management, warehouse management, and product processing and sorting. Durable material handling equipment is crucial to getting products out of your factory and to clients on time.

Polyurethane material, mainly in thermoplastic polyurethane and polyurethane foams, is one of the most well-known materials used to increase the longevity and durability of material handling equipment and produce high-quality polyurethane products. It is one of the most flexible elastomers and is used in various global applications.

Products made of polyurethane materials offer many advantages over those made of other elastomers and plastics, including greater strength, toughness, durability, and versatility. Chemical modification of the polyurethane coatings and mechanical properties offers a variety of unusual chances to solve challenges with performance qualities unmatched by any other materials.

Why Are Urethane Parts Essential to Material Handling?

The term “polyurethane,” frequently abbreviated as “PUR” or “PU,” refers to a group of polymers made up of organic units cross-linked by urethane.

Polyurethane may be made from various starting materials, unlike conventional polymers like polyethylene and polystyrene. This chemical diversity generates polyurethanes with a wide range of chemical structures, resulting in several uses. These include:

- Rigid and flexible foams

- Varnishes and coatings

- Elastomers

- Adhesives

- Electrical potting compounds

- Thermal stability

- Fibers such as spandex and PUL

- Polyurethane fabric

Polyurethane materials are created in such a way as to form a sizable class of polymers that may be adapted to a variety of uses, significantly enhancing the building, automotive, and electrical industries.

Numerous benefits of polyurethane material handling products include:

- Impact and abrasion-resistant parts

- Protection of products

- Resistance to chemicals

- Flame retardants

- Withstand heat

- Noise reduction

- Abrasion resistance

- Fire retardant

- Improved effectiveness

- Cost-effective

- Products that are consistent and lower the need for general machine maintenance

- Less downtime

- Longer lifespan

- Improved manufacturing process

What Urethane Parts Are Used in Material Handling?

In the beginning, thermosetting polyurethane was intended to be used as a synthetic version of natural rubber during World War II. The adaptability of this novel polymer and its capacity to substitute scarce materials soon led to the development of numerous applications. After World War II, the polyurethane industry rose, and polyurethane PU became a used material in many industries.

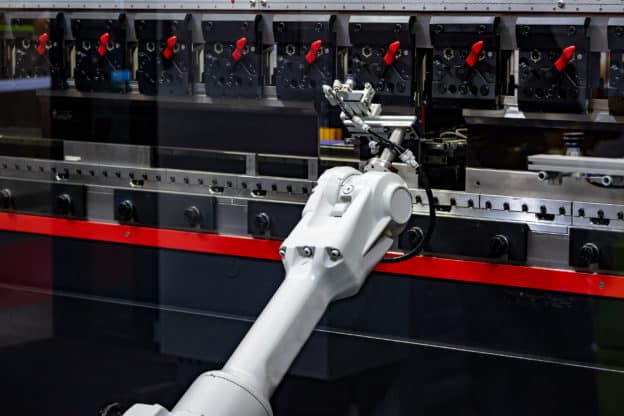

Polyurethane applications are essential for material handling equipment to ensure a continuous supply chain and efficient manufacturing process.

The following are just a few examples of material handling equipment parts that polyurethane properties may provide to assist you in fulfilling your material handling equipment production demands:

- Urethane Rollers

- Urethane Bumpers

- Urethane Gaskets, Washers, and Bushings

- Urethane Gripper Pads

- Urethane Linings for Various Components

- Polyurethane Clamps

- Diverters

- Wheels

- Conveyor Equipment Parts

- Rigid Foams

- Reusable Fabric

- And many more

Here are some more advantages of using polyurethane properties in situations involving material handling:

- Low tooling costs

- Excellent capacity for bearing loads

- Outstanding impact resistance

- Excellent noise reduction

- Outstanding efficiency

- Resist water

- Measurement stability

- Free from harmful toxins

- Long-term field wear

- Decreased downtime

- Lower costs of maintenance

Importance of Polyurethane Foams in Material Handling Equipment

The most popular type of polyurethane that is utilized extensively worldwide is polyurethane foam. It was commonly used for molding flexible foam cushions and seating, refrigerator walls, or thermal insulation. In just a short period, flexible polyurethane foam quickly replaced other upholstery such as car seats and furniture, shoe materials, and many more as the preferred option.

Due to their unique properties, polyurethanes can be modified to improve commercial and consumer goods and solve complex difficulties in material handling equipment.

Today, consumer and commercial products like bedding, furniture, automotive interiors, carpet underlay, and packaging are all cushioned with polyurethane properties, primarily in the form of polyurethane foam.

Flexible polyurethane foam can be created in various shapes and densities and is robust, comfortable, lightweight, and supportive. It is utilized in many items, including coatings, adhesives, mattresses, foam insulation, and shoe soles.

Importance of Polyurethane Fabric in Material Handling Equipment

In many aspects, polyurethane coating and properties improve the performance capabilities of fabric. There is a substantial layer of this polymer on many elastic fabrics. As a result, it can be used to create windproof and waterproof apparel while still enabling water vapor to permeate the fabric gently.

PU fabric is one great alternative to animal skins and other fabrics. It is more durable, flexible, and affordable. In addition, PU fabrics can be designed to look like natural animal skin.

Polyurethane fabric is a compound material cross-linked to the polyurethane that connects one or more layers of polymer resins with a woven or non-woven textile backing made of polyester, cotton, nylon, or ground leather. To make the Polyurethane coating appear more like animal skins, it is applied to just one side of the basic cloth.

Polyurethane fabrics break or wrinkle like genuine leather when stitched, collected, or tufted. Unlike vinyl, Polyurethane resins are constructed of a flexible polymer and don’t require an additional superplasticizer.

PU fabric doesn’t contain plasticizers, so there is no tearing or peeling, and it stays soft and comfortable for the entire time it is attached to the furniture. PU fabric and textiles may be decorated easily as well.

Since PU fabrics don’t produce dioxins, they are considered more environmentally friendly than vinyl. Although Polyurethane fabric can be more expensive to make than vinyl, it is less costly than natural leather.

Where Can Urethane Parts Be Purchased?

Urethane parts are now available online because of how prevalent and essential polyurethane materials are in material handling equipment. Urethane parts, however, are typically customized parts. They are created specifically for you based on your requirements and material handling machinery.

However, you may purchase urethane stock manufactured products like polyurethane sheets, rods, tubes, and bars online for standard material handling equipment parts.

Contact Uniflex

Polyurethane parts for material handling are available online. However, polyurethane parts online are commonly sold in stock and don’t have custom-made options. As a result, ensuring that your material handling equipment is fully equipped with polyurethane parts can be challenging since material handling can differ from models and designs.

Given the significance of urethane parts in material handling, you’ll need a trustworthy partner who can ensure that your supply chain and workflow are improved by allowing you to acquire all the Polyurethane parts you need for your material handling.

With 50 years of experience, Uniflex is a system provider for manufacturing hose lines, including workshop tools and production lines. Our area of expertise has advanced to rubber and urethane custom molding, and we can meet all of your needs for polyurethane material handling equipment.

We Can Mold Anything Urethane And Rubber

We strive for client satisfaction and offer durable, affordable, and high-volume custom molded parts that are trusted by industries all over the world. The fact that we can design, process, and manufacture all under one roof contributes to our ability to keep costs low and lead times short. We can give you all the polyurethane parts your business needs and make them precisely to fit your material handling equipment, ensuring a better and more reliable workflow.

Our business has been a dependable supplier for the polyurethane industry, aerospace, automotive, robotics, military, oil, gas, mining, and marine industries since 1979. Contact us today and learn more about how Uniflex can help you take your business to the next level of success!