Why are cast urethane products so widely used? Their resilience and molding versatility make them indispensable across industries for parts that must withstand wear, impact, and chemical exposure. In this guide, we’ll explore how these durable materials are shaping applications in manufacturing and beyond, without omitting their unique ability to be customized for any task.

Key Takeaways

- Cast urethane products are highly versatile, customizable, and suitable for a wide range of industrial applications due to their exceptional durability and resistance to abrasion, tear, impact, and chemicals.

- Customization of cast urethane products includes options for size, hardness (durometer), color, and formulation enhancements, enabling them to meet specific business and application requirements.

- Cast urethane manufacturing requires expert techniques, precision mold making, and rigorous quality control, making the selection of an experienced manufacturer like Uniflex, Inc. critical for obtaining high-quality, customized urethane products.

👉Also Read: Versatile Solutions: The Many of Cast Urethane Products

Exploring Cast Urethane Products

Cast urethane products come in many forms; they can be shaped and molded into bars, blocks, sheets, and more, showcasing their impressive versatility. These products find usage in an array of applications – from shock absorption materials and replacement materials to squeegees, bumpers, pads, and liners. They are even used in investor-pitch presentations and trade shows, thanks to vacuum casting, a technique that allows the creation of detailed models, nearly indistinguishable from the final product.

Abrasion-Resistant Urethane Components

From bushings and bearings to wheels and wear liners, polyurethane components excel in high-wear applications due to their exceptional abrasion resistance. Their durability, impingement resistance, and shock absorption properties make them ideal candidates for wheels and rollers.

The tear strength and resilience of polyurethane, combined with its ability to withstand different types of abrasion, contribute to its tear-resistance and impact-absorbing qualities. Even the color of these polyurethane components can serve as wear indicators, making it easier to assess wear and tear in abrasive conditions.

Chemical Resistant Urethane Materials

In a world where durability meets versatility, cast urethane stands out with its excellent chemical resistance. This property makes it an advantageous option in a myriad of industries, with polyurethane bars performing reliably even in demanding manufacturing applications.

Impact and Tear Resistant Urethane Parts

The strength of urethane products doesn’t stop at abrasion, chemical, and cut-resistant properties. Hard elastomeric urethane materials, known for their superior impact resistance, are ideal for industrial applications that demand endurance. High-rating urethane materials, for instance, are used to craft forming dies and gears, as they can withstand repeated stresses without tearing.

Urethane rods, characterized by their toughness, are the preferred choice in environments where durability against abrasion and cracking is pivotal.

👉Also Read: Experience the Excellence of Cast Urethane Products for Your Unique Needs

Customization Options for Cast Urethane Products

What if you need a urethane product tailored to your specific needs? Well, that’s where customization comes in. Custom cast urethane products can be designed in an array of shapes and sizes, from items under a gram to those over 2500 pounds. Whether you need sheeting, rings, gaskets, rollers, or bushings, you can customize your urethane products in terms of shape, size, durometer, and even color.

Custom formulation options are also available, allowing additives to be introduced into the cast urethane products to improve characteristics such as reducing friction, enhancing UV resistance, and increasing flame retardation.

Size Customization

Size matters, especially when it comes to manufacturing parts. Cast urethane products can be made in a diverse array of sizes, from tiny components to large items weighing over half a ton, offering extensive size customization. For small cast urethane parts, a minimum wall thickness of 0.020 inches is recommended, and for larger parts, a minimum of 0.040 inches is typically necessary.

The vacuum casting process allows for the production of approximately 50 casts from a single silicone mold, providing a cost-effective and swift solution for creating larger cast urethane parts.

Durometer Variations

In the world of molded urethane products, hardness matters as much as size. Durometer variations in cast urethane products enable their use in a wide range of applications due to their different hardness levels. Urethane materials are available in various hardness specifications, categorized by Shore durometer scales, where ‘A’ denotes softer materials and ‘D’ signifies highly rigid ones. By adjusting formulations, the physical properties and hardness of custom-molded urethane products can be specifically tailored to meet diverse application requirements.

Color Options

Urethane bars and sheets come in a rainbow of other colors too, including:

- Red

- Purple

- Orange

- Blue

These colors not only enhance visual appeal but also aid in identification for safety or branding purposes.

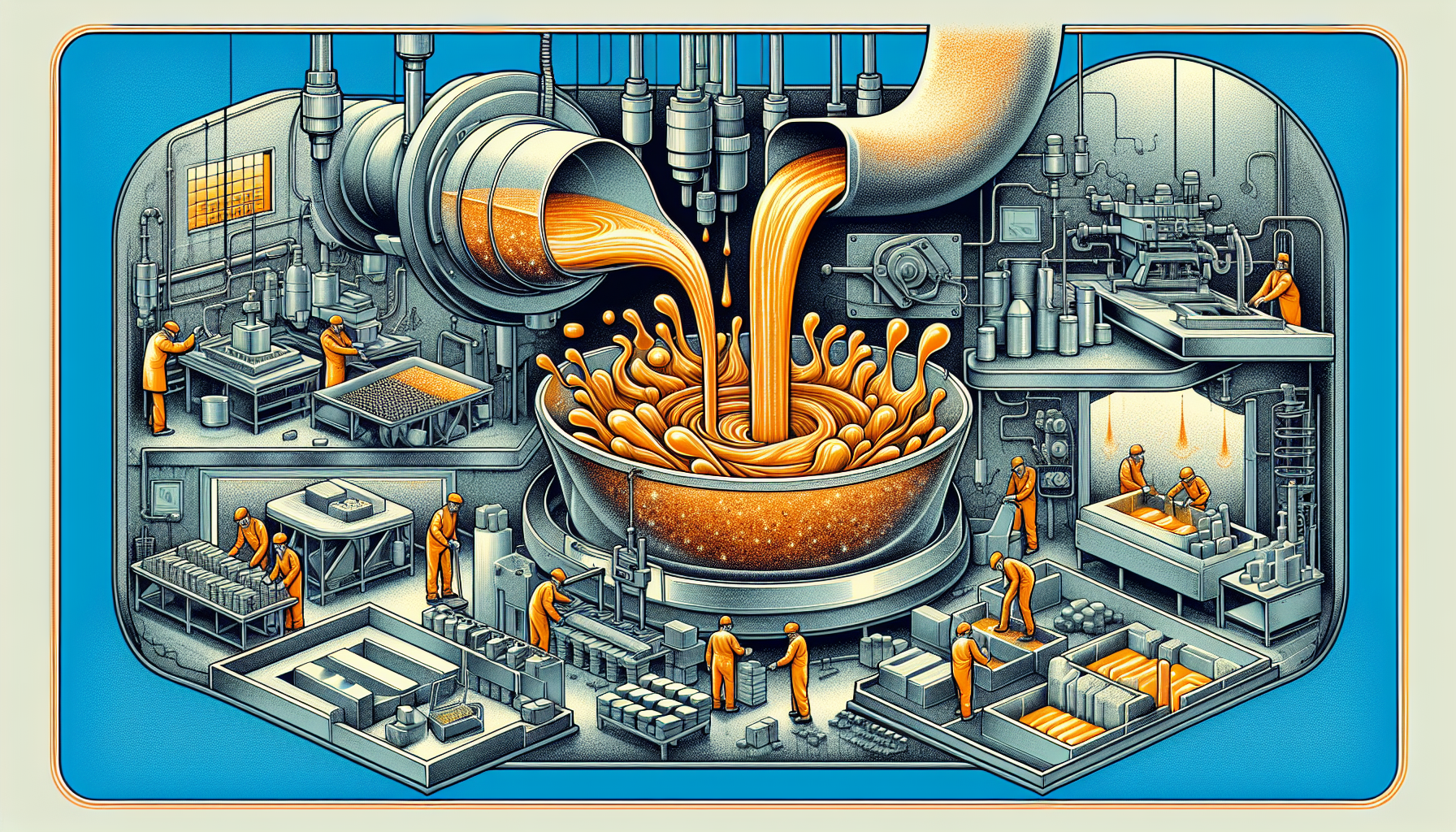

Manufacturing Process of Cast Urethane Products

The manufacturing of cast urethane products involves pouring or injecting liquid urethane into molds or using compression presses and ovens for curing. To ensure high-quality and consistent products, manufacturers employ advanced technologies and state-of-the-art equipment.

This process not only ensures superior quality but also allows for faster turnaround times, accommodating both unique projects and high-volume components.

Material Selection

Choosing the right material is crucial in the manufacturing process. Cast urethane products can be made from a variety of materials including:

- Polyether urethane

- Polyester urethane

- MDI urethane

- FDA approved urethane

Each of these materials is chosen based on the desired properties in the final product, such as flexibility, heat resistance, and tensile strength, making them the ideal material for specific applications. In comparison to other materials, these selections offer unique advantages tailored to their intended use.

Casting Techniques

Casting techniques play a significant role in creating cast urethane products. Vacuum casting, a prevalent technique, involves pouring urethane-based resins into silicone molds under a vacuum to achieve high-quality parts with minimized air bubbles. This technique not only ensures a high-quality cast but also allows for the combination of different material types within the same part, such as flexible and rigid urethanes.

Quality Control and Testing

Quality assurance is an integral part of the manufacturing process of cast urethane products. Implementing robust quality control measures ensures the consistency and reliability of cast urethane parts. From accounting for expected shrinkage in the final dimensions of urethane cast parts to ensuring lasting quality and accurate performance through the curing process, quality control is pivotal in the manufacturing process.

Industries Benefiting from Cast Urethane Products

Cast urethane finds its applications in a diverse array of parts and products, ranging from gaskets and overmolds to skateboard wheels and bumpers. A variety of industries including food processing, metal forming, military, die cutting, marine, mining, agriculture, automotive, and process automation extensively use cast urethane products.

Thanks to its adaptability, cast urethane processes provide specialized solutions for automotive components, consumer electronics, and other applications demanding tailored material properties.

Material Handling

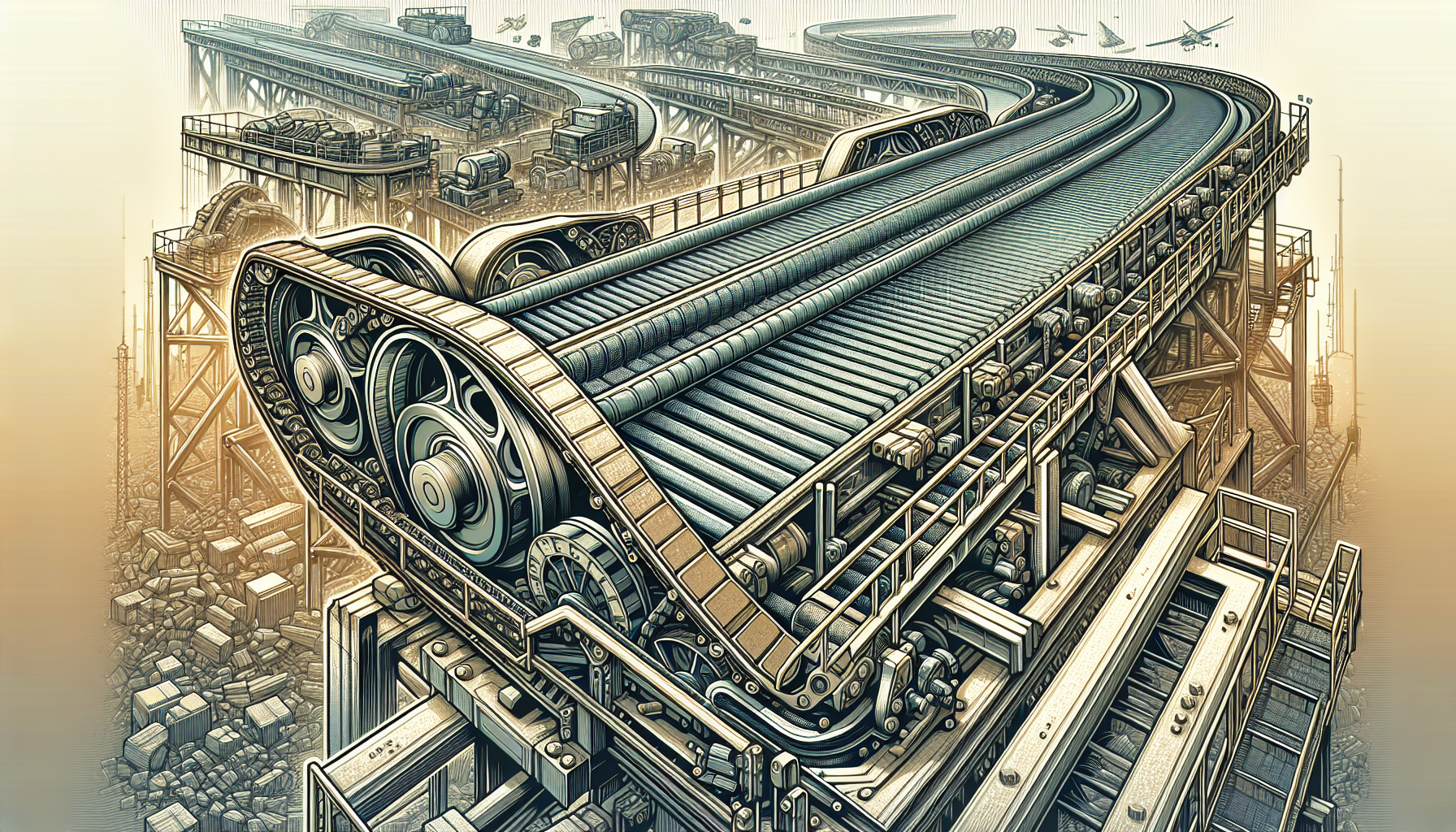

In the domain of material handling, cast urethane products like gaskets and overmolds play a pivotal role due to their flexibility and sealant properties. Material handling equipment, including conveyors, forklifts, and packaging machinery, employs cast urethane components to enhance performance and extend their operational life.

Specific use cases of cast urethane in material handling include urethane bars and rectangles in wastewater, food industry, paper, and conveyor machinery, as well as molded urethane bushings in high-impact areas where they surpass the performance of plastic and bronze.

Vibration Dampening

Urethane isolators are essential in mitigating resonance frequencies which can be destructive, a common challenge faced in various industries. Polyurethane bushings play a critical role by dampening energy transmission and redirecting this energy through the bushing itself, contributing to vibration dampening.

Selecting a Reliable Cast Urethane Manufacturer

When it comes to sourcing cast urethane products, selecting a reputable manufacturer is crucial. A good manufacturer is often characterized by their history of innovation, quality, versatility, and recognition for precision in product development. It is also important to evaluate the level of customer service, ease of access to technical support, and the ability to build a good relationship with clear communication channels.

Expertise and Experience

When choosing a cast urethane manufacturer, their expertise and experience matter. A long-standing presence in the cast urethane industry often correlates with a deep understanding and expertise in the field. A track record of successful projects and client satisfaction is a reliable measure of a manufacturer’s experience and expertise.

Customization Capabilities

One of the key aspects to look for in a manufacturer is their customization capabilities. A leading manufacturer with a wide range of solutions and strong customization capabilities can support business growth and meet specific application requirements. This means that customers can initiate the customization process for their specific urethane product needs by:

- Contacting professionals directly

- Discussing their requirements and specifications

- Collaborating with the manufacturer to design and develop a customized solution

- Receiving a tailored product that meets their unique needs

Lead Time and Pricing

The lead time and competitive pricing are also crucial factors when selecting a cast urethane manufacturer. Shorter lead times are important for companies with time-sensitive requirements for parts.

Additionally, cast urethane manufacturing is particularly advantageous for companies requiring small quantities of parts as it eliminates the higher costs often associated with larger-scale production methods.

👉Also Read: Maximizing Durability: Custom Urethane Part for Your Toughest Applications

Unlock Excellence Today – Partner with Uniflex, Inc. for Your Cast Urethane Needs!

Discover excellence in cast urethane products with Uniflex, Inc.! With over 40 years of experience, we’re your trusted partner in the rubber and urethane manufacturing industry. From custom-molded parts tailored to your specifications to top-quality formulations, we deliver unparalleled expertise and precision.

At Uniflex Inc., innovation meets efficiency in our state-of-the-art facility. Our streamlined production process ensures both cost-effectiveness and superior output, setting us apart as leaders in the field. From mold making to production, our versatile departments guarantee swift turnaround times without compromising on quality.

Experience peace of mind with our rigorous inspection and quality assurance protocols. We don’t just meet expectations; we exceed them, ensuring every product leaving our facility meets the highest standards. Whether you need bushings, liners, rollers, or bumpers, Uniflex, Inc. has you covered.

Partner with us today and experience the difference of Uniflex, Inc.’s commitment to excellence. Your satisfaction is our priority, and we’re here to deliver results that exceed your expectations, every time.