Polyurethane bumpers are increasingly popular in industrial settings. In this article, we explore 5 benefits of using polyurethane bumpers in industrial applications. Learn why they outperform traditional rubber and other materials.

Key Takeaways

- Polyurethane bumpers offer exceptional durability and longevity, significantly reducing maintenance costs and downtime in industrial applications.

- These bumpers provide superior impact resistance and chemical resistance, ensuring machinery protection even in harsh environments.

- Polyurethane bumpers are versatile in design, customizable for specific industrial needs, and contribute to noise reduction, enhancing workplace safety and comfort.

Enhance the safety, durability, and efficiency of your operations with Uniflex, Inc.’s Polyurethane Rubber Mold Bumpers. Designed to prevent product damage, reduce noise, and withstand the harshest conditions, these custom-molded bumpers are the ultimate solution for industries where repeated impacts are a concern. Trusted by sectors like automotive, robotics, mining, and oil, our bumpers not only protect your equipment but also contribute to a quieter, more productive workplace.

Click here to view our stock bumper lines, request a custom design, or consult with our expert engineers. Let us help you turn your vision into reality, with production-ready solutions that save you time and money. Don’t wait—contact us now at 248-486-6000 to learn more or request a quote!

👉Also Read: High-Performance Urethane Bars: Durable Solutions for Your Industrial Needs

Durability and Longevity

Polyurethane bumpers are notably durable, making them a standout feature. Unlike conventional rubber bumpers, which often need frequent replacements, polyurethane bumpers have a lifespan that is twice as long. This means fewer interruptions in your operations and lower overall maintenance costs.

Polyurethane bumpers excel in wear resistance, surpassing most plastics and PVC options. They are highly resistant to abrasion, even under mechanical action such as rubbing and scraping. This superior tear resistance translates into a more reliable and long-lasting solution for industrial applications.

Additionally, polyurethane bumpers have the following benefits:

- They withstand significant pressure without succumbing to breakage or tears

- They retain their smooth texture and structural integrity even in low temperatures or abrasive conditions

- This resilience ensures that your equipment remains protected and operational for extended periods.

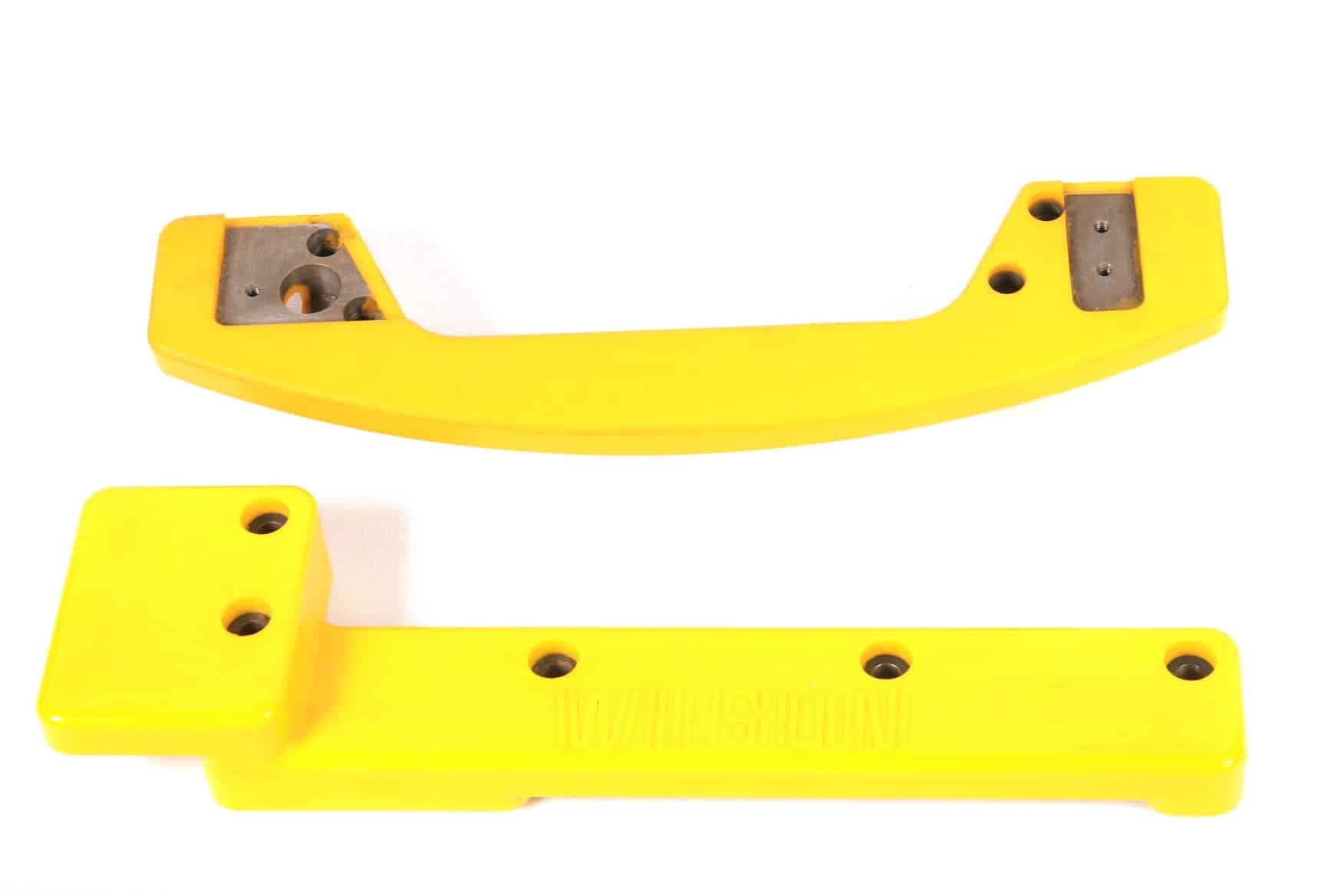

The advantages of polyurethane bumpers include:

- The ability to bond with metal, enhancing strength and durability

- Suitable for heavy-duty applications

- Mitigating vibrations, prolonging equipment lifespan and reducing downtime

- Ensuring better performance and reliability, benefiting industrial operations.

Superior Impact Resistance

The exceptional impact resistance of polyurethane bumpers is well-known. Unlike rubber or steel, these bumpers excel at absorbing and dispersing shock energy, thereby protecting machinery from potential damage. This feature is crucial in heavy-duty applications where equipment is frequently subjected to high impact forces.

The round urethane bumpers, as well as square ones, effectively absorb and disperse energy, safeguarding internal components and extending the lifespan of the machinery. This shock absorption capability ensures that even under significant stress, the equipment remains functional and undamaged.

Moreover, a wide range of hardness levels do not affect the impact resistance of polyurethane bumpers, which guarantees consistent performance. This adaptability makes them a preferred choice for various industrial applications, offering both durability and better performance. With their high tear strength and low coefficient of friction, these bumpers resist tearing and continue to perform under rigorous conditions.

Chemical and Oil Resistance

Chemicals and oils are commonly encountered in harsh industrial environments. Polyurethane bumpers stand out due to their high resistance to these substances. This resistance ensures that the bumpers maintain their integrity and effectiveness, even in challenging conditions.

Polyurethane bumpers have several advantages:

- They resist oils, solvents, and fuels, preventing degradation over time.

- This extends the lifespan of the bumpers, making them cost-effective.

- They remain stable with minimal swelling in water or oil, unlike other materials that may swell or lose their properties when exposed to chemicals.

The chemical resistance of these bumpers is influenced by the concentration, temperature, and duration of exposure to the chemicals. However, even under prolonged exposure, polyurethane bumpers continue to perform reliably. This makes them an excellent choice for industries where chemical exposure is a significant concern, ensuring durability and consistent performance.

Versatility in Design and Application

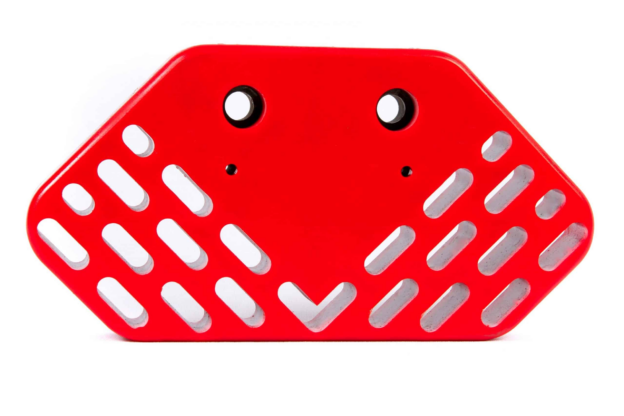

The design and application versatility of polyurethane bumpers is remarkable. They can be custom-molded into various shapes such as rods, sheets, and tubes, meeting the specific needs of different industrial applications. This flexibility allows manufacturers to design bumpers that perfectly fit their equipment and operational requirements.

These bumpers are available in different hardness levels, ranging from 40A to 95A. This variety ensures that there is a suitable bumper for every application, whether it requires soft cushioning or rigid support. Additionally, polyurethane bumpers can be customized in terms of color, hardness, and form, providing tailored solutions for diverse industrial needs.

Vibration isolation, cushioning, and insulation tasks particularly benefit from custom-molded polyurethane foam bumpers. These bumpers can:

- Absorb vibrations and shocks, protecting sensitive equipment and enhancing performance

- Be reinforced with metallic support, further enhancing their structural integrity

- Be used in demanding industrial environments

Custom-molded polyurethane foam square bumpers are ideal for these applications, as they provide the necessary protection and durability for various molded parts.

The versatility of polyurethane bumpers means they can be utilized in a wide range of industries, from automotive to manufacturing facilities. This adaptability, combined with their durability and performance, highlights the numerous advantages of choosing polyurethane products for industrial applications.

Noise Reduction

Urethane bumpers used in industrial settings significantly contribute to noise reduction. These bumpers:

- Minimize metal-to-metal contact, which is a major source of noise in machinery

- Create a quieter working environment

- Lead to smoother and more efficient operations

The noise-dampening properties of urethane bumpers have several benefits:

- Preventing the transfer of vibrations and movements between machine parts

- Enhancing performance

- Improving workplace safety and comfort

- Contributing to a more pleasant and productive workspace, especially in environments where heavy machinery is used.

Enhanced Performance Under Extreme Conditions

Even under extreme conditions, polyurethane bumpers are designed to maintain their performance. They can be compressed up to 70% of their original height without a permanent set, ensuring they retain their structural integrity. This low permanent set means that the bumpers return to their original shape after compression, providing consistent protection and performance.

Polyurethane bumpers have several advantages over rubber bumpers:

- They maintain their resilience at high hardness levels

- They can withstand extreme temperatures without cracking or hardening

- They are suitable for use in harsh environments

- They ensure that the equipment remains protected and operational, regardless of the environmental challenges.

Specific urethane products, such as MDI PTMEG Polyether urethane, possess outstanding dynamic properties and high resilience. These characteristics make them ideal for heavy-duty applications where durability and flexibility are crucial. Uniflex, Inc.’s urethane products are designed to withstand the test of time, offering unmatched performance and reliability in various industrial settings.

Cost-Effectiveness

One of the key advantages of polyurethane bumpers is their cost-effectiveness. Here are some reasons why:

- Long lifespan

- Superior impact resistance

- Reduced maintenance costs

- Less operational downtime

Investing in polyurethane bumpers can lead to significant savings over time, as they require fewer replacements and less frequent repairs.

Moreover, polyurethane bumpers have the following advantages:

- Lower tooling costs compared to rubber and plastics, making them an economical choice for prototypes and low-volume production

- Durability and performance

- Affordability

These qualities make polyurethane bumpers a smart investment for any industrial application.

👉Also Read: The Top 4 Industries That Benefit From Custom Polyurethane Products

Discover Uniflex, Inc.’s Custom Polyurethane Bumpers—Enhance Your Operation Today!

Uniflex, Inc. is your go-to source for high-quality custom polyurethane bumpers that deliver unmatched performance, reliability, and customization. Whether you need round, rectangular, or uniquely shaped bumpers, our expert team is ready to craft solutions tailored specifically to your industrial needs. Ready to elevate your industrial performance? Contact us today to learn more!

Frequently Asked Questions

What makes polyurethane bumpers more durable than rubber?

Polyurethane bumpers are more durable than rubber due to their superior wear and tear resistance, lasting twice as long as rubber bumpers.

How do polyurethane bumpers reduce maintenance costs?

Polyurethane bumpers reduce maintenance costs by minimizing the need for frequent maintenance and unscheduled repairs due to their better abrasion and tear resistance.

Can polyurethane bumpers withstand chemical exposure?

Yes, polyurethane bumpers have high resistance to a wide range of chemicals and oils, preventing degradation. They can withstand chemical exposure effectively.

Are polyurethane bumpers customizable?

Yes, polyurethane bumpers can be customized into different shapes, hardness levels, and colors to meet various industrial requirements.

How do polyurethane bumpers help reduce noise in the workplace?

Polyurethane bumpers help reduce noise in the workplace by minimizing metal-to-metal contact and dampening vibrations, creating a quieter working environment.