Choosing the right snow plow blade type is crucial for effective snow removal. In this guide, we’ll explore the strengths and weaknesses of steel, rubber, and polyurethane blades. By understanding these options, you’ll be able to pick the ideal blade for your specific needs. Let’s dive in and find the best fit for your plowing tasks.

Looking for durable, high-performance snow plow blades? Uniflex, Inc. offers premium polyurethane cutting edges designed to extend the life of your plow and protect surfaces from damage. Buy directly from the manufacturer for the best pricing, with bulk discounts available for orders of 10 or more pieces.

Our urethane blades are easy to install, customizable, and provide superior sliding abrasion resistance, making them ideal for both commercial and residential applications. Whether you need a blade for light work or heavy-duty use, we have options to fit every need. Ready to upgrade? View our pricing or buy online today, and if you need assistance, our expert team is here to help.

👉Also Read: Enhance Your Snow Removal: Top Polaris Plow Cutting Edge Features and Benefits

Understanding Snow Plow Blade Materials

When it comes to snow plow blades, the material you choose can significantly impact their performance and longevity. Different materials cater to unique operational needs, emphasizing versatility and effectiveness in various environments. Choosing the right material for residential driveways, commercial properties, or high-traffic roadways ensures optimal snow and ice removal.

The main materials used for snow plow blades include steel, rubber, and polyurethane. Each of these materials has distinct characteristics that make them suitable for specific applications. These differences guide you in selecting the best blade, promoting efficient snow removal while minimizing damage to the plowing surface.

Here are the details on these materials.

Steel Cutting Edges

Steel cutting edges are a popular choice for snow plow blades due to their durability and excellent scraping ability. High carbon steel, in particular, offers a longer lifespan compared to softer materials, making it ideal for harsh conditions and abrasive surfaces. These blades are known for their ability to scrape effectively, reducing the need for additional salt or ice melt products during the plowing process, especially when equipped with a snow plow cutting edge.

However, the weight of steel edges can impact fuel efficiency and overall plow performance, especially in smaller vehicles. Nevertheless, steel cutting edges are favored for high-performance and durable applications like trip-edge or full-trip plows. Their robust build suits large areas where noise and surface sensitivity are less of a concern.

Rubber Snow Plow Blades

Rubber snow plow blades are favored for their quieter operation and ability to prevent surface damage during snow removal. These blades are made from a blend of natural rubber and styrene butadiene rubber (SBR), which enhances their durability and performance. Rubber blades are particularly suitable for residential areas and other environments where noise reduction is important.

However, rubber blades do have some limitations. They do not scrape as effectively as steel blades, which can leave hard-packed snow and ice on the surface. Additionally, using rubber blades may require more salt or ice melt for effective clearing.

However, rubber-cutting edges excel on sensitive surfaces by flexing instead of gouging or scraping, thereby reducing plow damage. The rubber cutting edge is particularly effective in this regard.

Polyurethane Snow Plow Blades

Polyurethane snow plow blades offer a balance of durability and flexibility, making them suitable for a variety of snow and ice conditions. These blades are more durable than rubber but may not endure heavy use as effectively as steel. Polyurethane cutting edges produce less noise than steel alternatives, making them favorable for use in residential areas.

While polyurethane blades don’t scrape as well as steel, they provide significant advantages in terms of flexibility and noise reduction. Though the most expensive, polyurethane snow plow blades offer unique benefits like preventing surface damage and improving operator comfort.

The investment in polyurethane blades can lead to long-term savings due to their extended lifespan and reduced need for replacements.

Choosing the Right Thickness for Your Needs

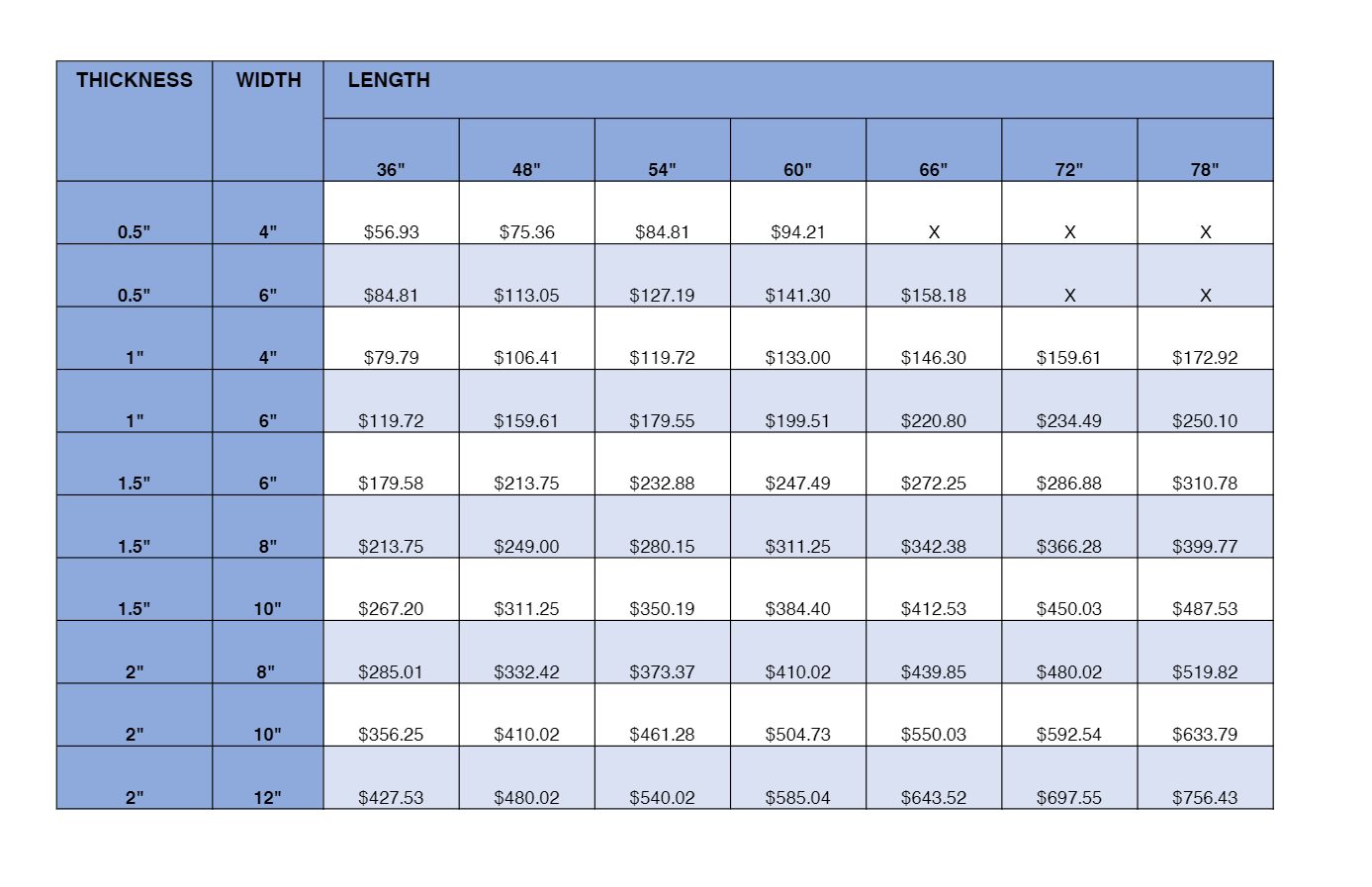

Selecting the correct thickness for your snow plow blade is crucial for ensuring both performance and durability across various applications. The thickness of the blade influences its ability to handle tough conditions and impacts, making it a key factor in the longevity of the cutting edge.

Different plowing tasks require different blade thicknesses. For light-duty applications such as clearing residential driveways, thinner blades are sufficient and prevent surface damage. Standard and commercial uses typically need a medium thickness for durability and effectiveness. Heavy-duty plowing, on the other hand, demands the thickest blades to withstand extreme conditions.

Let’s explore these needs in more detail.

Light Work Applications (Small Tractors, ATVs, UTVs)

Blades with a thickness of 0.5 inches are typically recommended for light-duty tasks. These blades are ideal for clearing residential driveways and sidewalks, where the demands on the blade are lower. For effective snow clearing in light work applications, selecting the appropriate blade thickness ensures efficiency and prevents surface damage.

Standard and Commercial Use (Larger Tractors, ATVs, UTVs, Commercial Vehicles and Tractors)

For standard and commercial purposes, blades that are 1 inch to 1.5 inches thick provide an optimal mix of durability and performance. This thickness range strikes a balance between performance and durability for everyday commercial use, enhancing the effectiveness of snow clearing while ensuring the blade remains durable under typical commercial workloads.

Heavy-Duty Plowing (For Excessive Use, Heavy or Large Equipment, and Trucks)

For heavy-duty plowing, a thickness of 2 inches is recommended to ensure maximum strength and resilience against tough conditions. Using a 2-inch thick blade provides enhanced durability, making it ideal for heavy-duty snow removal tasks where the blade must withstand extreme conditions and impacts. These thicker blades are less likely to bend or deform under heavy impact, ensuring reliability during tough operations.

Ultimately, the correct blade thickness is vital for durability and effectiveness in heavy-duty tasks. Opting for a 2-inch thick cutting edge maximizes durability and effectiveness under tough conditions, making it perfect for heavy-duty plowing.

Installation and Maintenance Tips

Proper installation and maintenance of snow plow blades are essential for their effective operation and longevity. Regular inspection of snow plow blades for wear can prolong their lifespan and maintain optimal performance. Additionally, cleaning snow plow blades after each use helps prevent corrosion and build-up of ice.

Proper lubrication of all moving parts is crucial to maximize efficiency and reduce wear on the plow. Flushing and replacing hydraulic fluid annually ensures the proper functioning of the plow’s hydraulic system. Keeping electrical connections clean and tight is also essential to prevent plow malfunctions.

Here’s a deeper look into the installation process and maintenance best practices.

Installation Process

Properly installing snow plow blades can greatly improve their effectiveness. Start by gathering the necessary hardware, including nuts, bolts, and fish wire. Use a fish wire to help in threading bolts through the frame of the vehicle for secure attachment.

For the new urethane blade, lay the old blade on top of it, trace the hole pattern, drill holes, and attach the new blade.

Maintenance Best Practices

Regular maintenance is key to extending the lifespan of your snow plow blades. Greasing moving contact points of the plow helps prevent excessive wear and corrosion. Regular inspections of the cutting edge ensure it remains sharp and effective against snow and ice. Routinely checking and tightening fasteners can prevent equipment failure during operation.

Polyurethane cutting edges reduce equipment vibration, minimizing driver fatigue and wear. Signs that indicate blade wear include visible nicks, cracks, or significant reduction in height. Replacing the cutting edge when it wears down to about four inches is recommended to maintain plow efficiency.

Benefits of Urethane Cutting Edges

Urethane cutting edges offer several benefits, making them a popular choice for various industrial and construction applications, particularly in snow plows, skid loaders, and other heavy machinery. Here are some key advantages:

1. Durability and Longevity

Urethane cutting edges are highly durable, providing extended wear life compared to traditional materials like rubber or steel. They are designed to withstand harsh environments, abrasions, and heavy impact, reducing the frequency of replacements and maintenance costs.

2. Noise Reduction

Unlike steel edges, urethane produces significantly less noise when it comes into contact with surfaces like pavement or concrete. This makes urethane cutting edges ideal for urban environments where minimizing noise pollution is a priority.

3. Surface Protection

Urethane is non-marking and less abrasive, ensuring that surfaces such as concrete, asphalt, and specialty flooring remain intact during use. This characteristic is particularly important for sensitive or high-value surfaces that require minimal damage.

4. Corrosion Resistance

Unlike metal cutting edges, urethane does not rust or corrode when exposed to moisture or chemicals, making it suitable for operations in wet and corrosive environments, such as snow removal.

5. Flexibility and Customization

Urethane cutting edges can be customized in terms of hardness, thickness, and shape to suit specific applications and equipment needs. This flexibility allows for optimized performance in various conditions, such as extreme temperatures or heavy-duty tasks.

6. Impact Absorption

The material’s flexibility allows urethane cutting edges to absorb and dissipate impact energy, reducing damage to both the cutting edge and the equipment. This also improves safety and lowers repair costs associated with equipment damage.

7. Efficiency in Snow and Debris Removal

Urethane edges effectively clear snow, slush, and debris while maintaining consistent contact with the surface. They offer similar or superior scraping capabilities compared to steel edges without causing surface damage.

8. Ease of Installation and Replacement

These cutting edges are often designed for easy installation, allowing for quick swaps and minimal downtime. Their lighter weight compared to steel edges also simplifies handling and installation procedures.

Comparing Cost and Performance

When choosing snow plow blades, it’s essential to balance cost and performance. Higher upfront costs for premium materials often result in lower long-term expenses due to reduced maintenance and replacement frequency.

Investing in high-quality blade materials can lead to fewer replacements, ultimately saving money over time. Durable steel and polyurethane blades are commonly chosen for commercial settings because they offer a balance of performance and longevity.

Here’s a deeper comparison between initial investment and longevity, and the performance metrics of different materials.

Initial Investment vs. Longevity

Understanding the materials used for snow plow blades, such as steel, rubber, and polyurethane, is crucial for comparing investment costs and longevity. While steel cutting edges are generally more affordable upfront, they may lead to higher long-term costs due to replacement frequency and potential surface damage.

In contrast, polyurethane blades, though priced higher initially, offer excellent longevity and surface protection, reducing overall costs.

Performance Metrics

Different snow plow blade materials exhibit varying levels of scraping efficiency, which influences their overall effectiveness in snow removal. Materials like heat-treated steel often outperform lower-quality options in terms of scraping efficiency and durability during snow removal.

Polyurethane blades are effective at absorbing vibrations, reducing noise during operation, and preventing metal shavings, which can be a concern with steel edges.

Environmental Impact of Snow Plow Blades

The environmental impact of snow plow blades is an important consideration. Snow plow blades made from materials like steel, rubber, and polyurethane are recyclable, but proper disposal methods should be followed to minimize environmental harm. Selecting eco-friendly snow plow blades can significantly reduce their ecological footprint and promote sustainable practices in snow removal.

Choosing blades made from biodegradable materials or those with low environmental impact can help reduce ecological damage during winter operations. Making informed choices about snow plow blades can significantly contribute to environmental conservation efforts during the winter months.

Common Issues and Troubleshooting

Even the best snow plow blades can encounter issues. Steel cutting edges, for instance, can cause damage to sensitive surfaces and generate more noise compared to alternatives like rubber. Regular inspections of snow plow components are vital to identify potential issues before they escalate. Ensuring compatibility with the specific vehicle’s bolt pattern is also crucial for effective blade installation.

Matching cutting edges with plowing surfaces ensures optimal performance and minimizes equipment damage. Utilizing a universal installation method allows for compatibility with various bolt patterns, enhancing installation versatility.

Here are more details on common wear and tear issues and the importance of surface compatibility.

Wear and Tear

Snow plow blades typically show wear after about six months, necessitating potential replacement for optimal performance. Regular checks for blade performance are crucial to determine when replacements are necessary.

Signs that indicate blade wear include visible nicks, cracks, or significant reduction in height.

Surface Compatibility

Matching cutting edges with plowing surfaces ensures optimal performance and minimizes surface or plow damage. Ensuring compatibility with various plowing surfaces is essential for effective snow plow cutting removal.

The right steel cutting edge for a specific surface type can lead to better efficiency and lower maintenance costs, especially when considering traditional cutting edges.

👉Also Read: Purchase Your Polyurethane Plow Edge This Winter

Upgrade Your Snow Plow Today—Explore Our Durable, High-Performance Blades!

Ready to upgrade your snow removal equipment? At Uniflex, Inc., we offer high-quality polyurethane snow plow blades designed for durability, noise reduction, and surface protection. Whether you’re managing residential, commercial, or heavy-duty plowing tasks, our customizable blades provide superior performance in any environment. Order directly from us to enjoy the best prices, bulk discounts, and fast shipping. Need help finding the perfect fit? Contact our expert team today at 248-486-6000 and get the right blade for your snow removal needs.