In the mining industry, where heavy machinery endures extreme conditions daily, equipment failure can lead to costly downtime and decreased productivity. Traditional metal and rubber components often wear out quickly under harsh environments, resulting in frequent replacements and high maintenance expenses. Custom-made polyurethane parts offer a durable, cost-effective solution to protect your mining equipment from excessive wear, impact, and corrosion.

Engineered for superior strength, flexibility, and abrasion resistance, polyurethane components enhance equipment longevity and efficiency. In this blog, we explore the top solutions for safeguarding your mining equipment with custom polyurethane parts, ensuring maximum performance and reliability in the toughest conditions.

Key Takeaways

- Polyurethane parts offer exceptional abrasion resistance, significantly enhancing the durability and reliability of mining equipment in harsh environments.

- Custom-made polyurethane components reduce maintenance costs and downtime by providing tailored solutions that fit specific operational needs.

- Choosing a knowledgeable cast polyurethane manufacturer like Uniflex, Inc. ensures access to high-quality, customized polyurethane products that improve mining equipment performance.

At Uniflex, Inc., we manufacture custom-engineered polyurethane parts designed to meet the unique needs of the mining industry, including:

- Polyurethane Chute Liners & Wear Plates – Extend the service life of hoppers, chutes, and processing equipment.

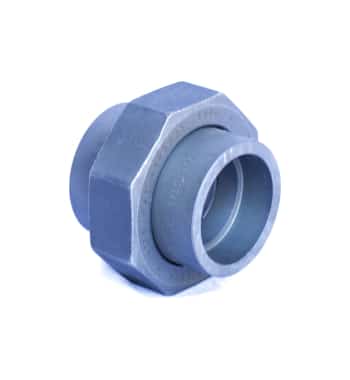

- Seals & Gaskets – Prevent leaks and withstand harsh chemical exposure.

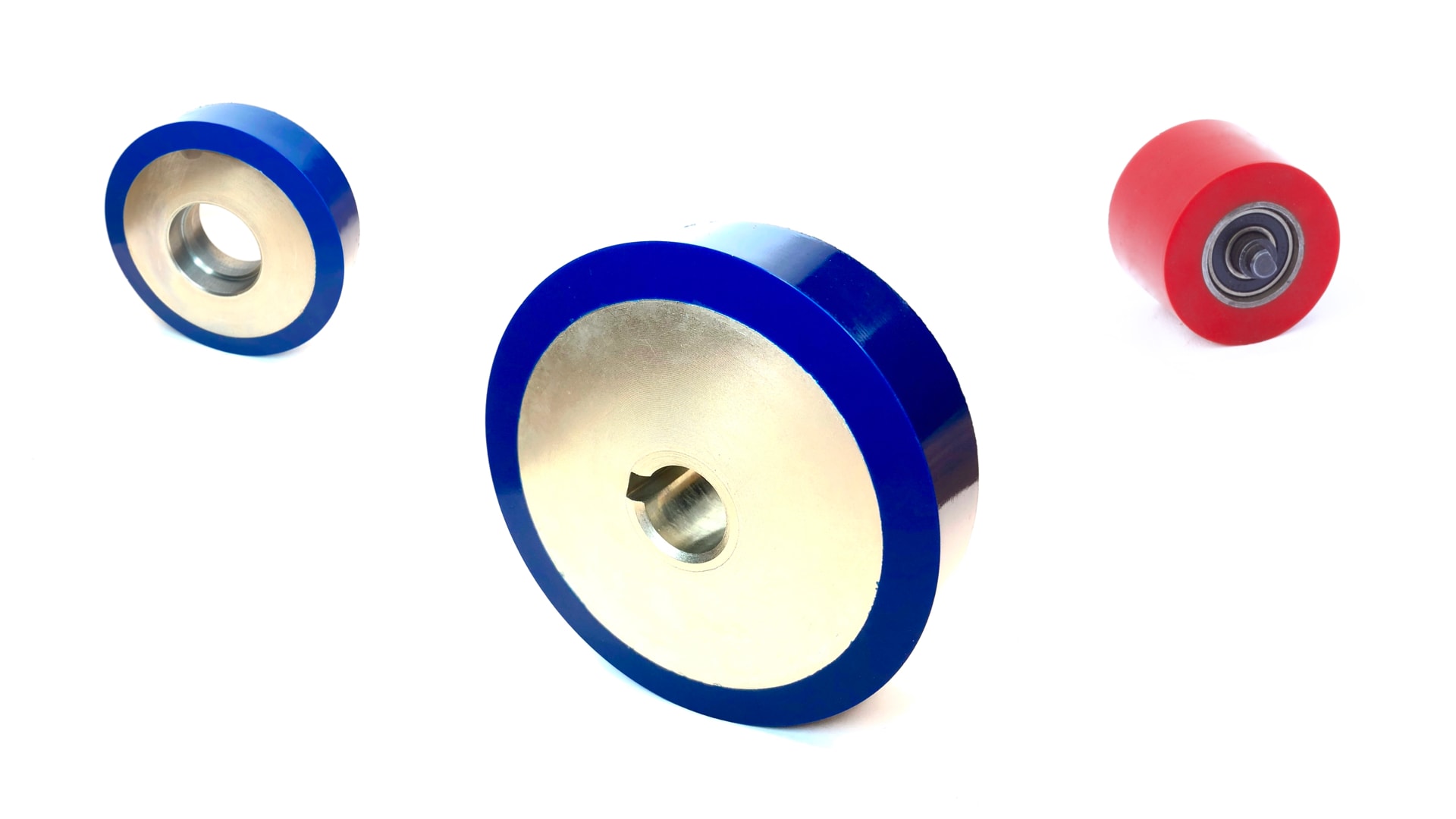

- Polyurethane Bushings & Bearings – Reduce friction and improve equipment longevity.

- Mining Conveyor Rollers & Impact Bars – Minimize wear and tear on conveyor systems.

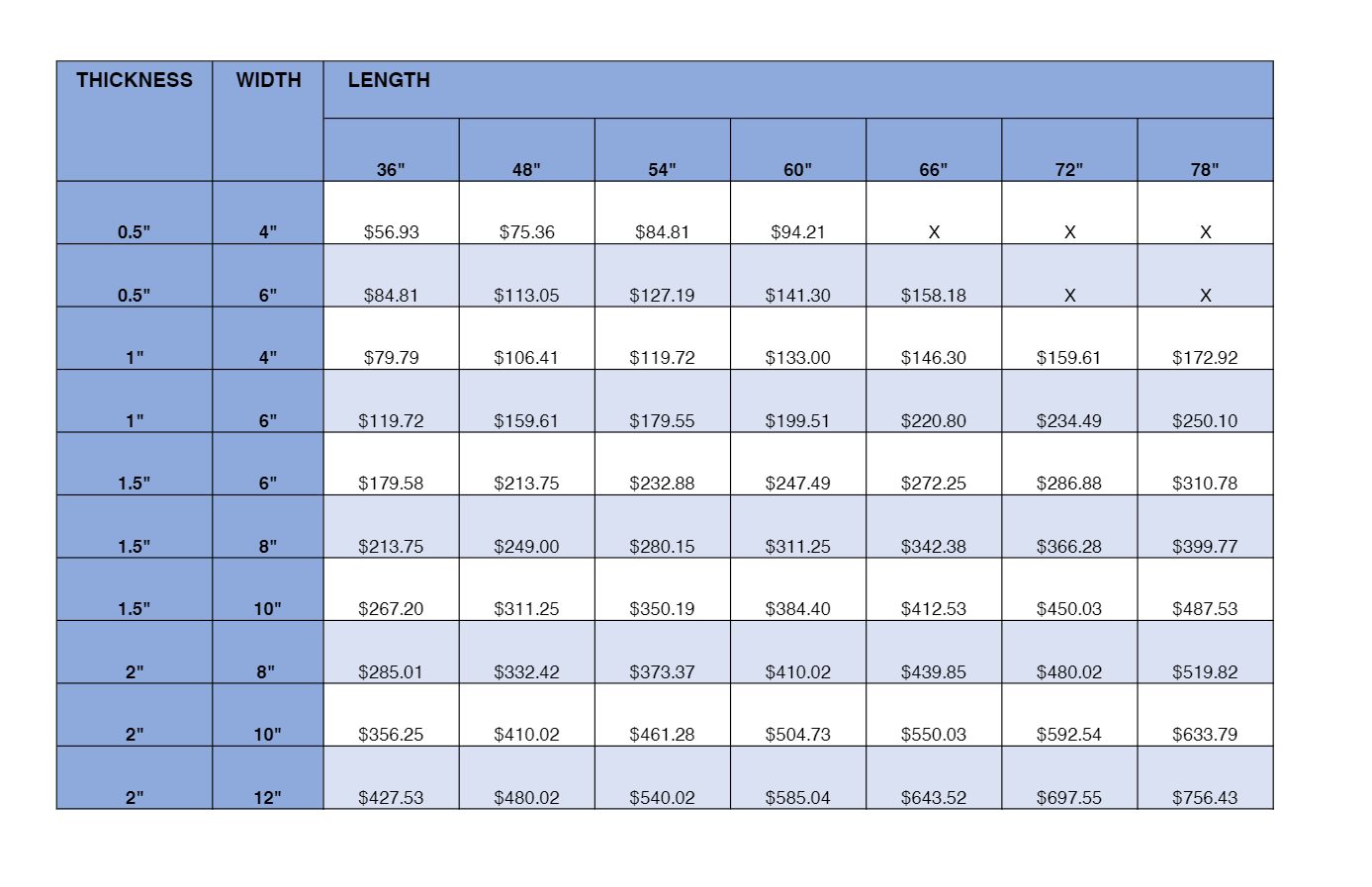

Every mining operation has unique challenges, which is why we customize polyurethane components to meet your exact specifications. Our in-house mold-making and casting capabilities allow us to design and produce parts in various durometers, sizes, and formulations to optimize performance for your application. From short-run prototypes to high-volume production, we deliver solutions that keep your mining operations running efficiently.

For decades, Uniflex, Inc. has been a trusted partner for the mining industry, delivering custom polyurethane components that exceed performance expectations. Whether you need abrasion-resistant liners, durable conveyor parts, or impact-resistant seals, our team is ready to engineer a solution that meets your needs.

Ready to upgrade your mining equipment with long-lasting polyurethane solutions? Contact Uniflex, Inc. today at 248-486-6000! Let’s discuss how we can improve the efficiency and durability of your mining operations.

👉Also Read: Revolutionizing Automotive Performance: The Role of Custom Molded Polyurethane

The Importance of Abrasion Resistance in Mining Equipment

Mining operations are notorious for their harsh working conditions, where equipment is relentlessly exposed to abrasive materials, high impacts, and environmental extremes. These challenges, such as abrasive mineral particles and combustible dust, often lead to frequent breakdowns in mining and aggregate sectors. High impacts, abrasion, and corrosive materials pose significant durability challenges to mining operations, leading to equipment failures and performance declines. Exceptional abrasion resistance becomes essential to ensure the longevity and reliability of mining equipment in such conditions.

The use of traditional materials like metal and rubber often falls short in providing the needed durability due to their limitations. Metal components, for instance, can corrode and wear out quickly when exposed to abrasive substances, while rubber parts may not withstand high impacts and harsh environmental conditions. This is where polyurethane stands out. Polyurethane lining enhances abrasion resistance and prevents corrosion, significantly extending the life of aluminum pipes and other components used in mining operations.

For example, modular urethane panels offer superior abrasion and wear resistance compared to traditional steel screens, contributing to reduced maintenance needs and minimized downtime. In the mining industry, where equipment is constantly subjected to extreme wear and tear, the importance of abrasion resistance cannot be overstated.

Advantages of Custom-Made Polyurethane Parts

1. Exceptional Strength and Abrasion Resistance

Polyurethane stands out in the mining industry due to its superior strength, abrasion resistance, and tear resistance. Unlike traditional materials that wear down quickly, polyurethane components maintain their integrity even in the harshest environments. This durability reduces daily wear on mining equipment, ensuring longer service life and minimizing costly downtime.

2. Lightweight and High Performance

One of polyurethane’s key benefits is its lightweight nature compared to metal and other conventional materials. Polyurethane rods and tubes, for instance, provide exceptional abrasion resistance while also reducing the overall weight of mining machinery. This weight reduction improves energy efficiency, enhances mobility, and simplifies installation, particularly in underground mining operations where ease of handling is critical.

3. Impact and Crushing Resistance for Cable Protection

Mining environments expose cables and electrical components to heavy impact, crushing, and extreme conditions. Polyurethane cable protectors offer outstanding resistance to these stresses, preventing damage and ensuring reliable performance. Their superior resilience helps safeguard critical electrical infrastructure, reducing maintenance needs and the risk of operational failures.

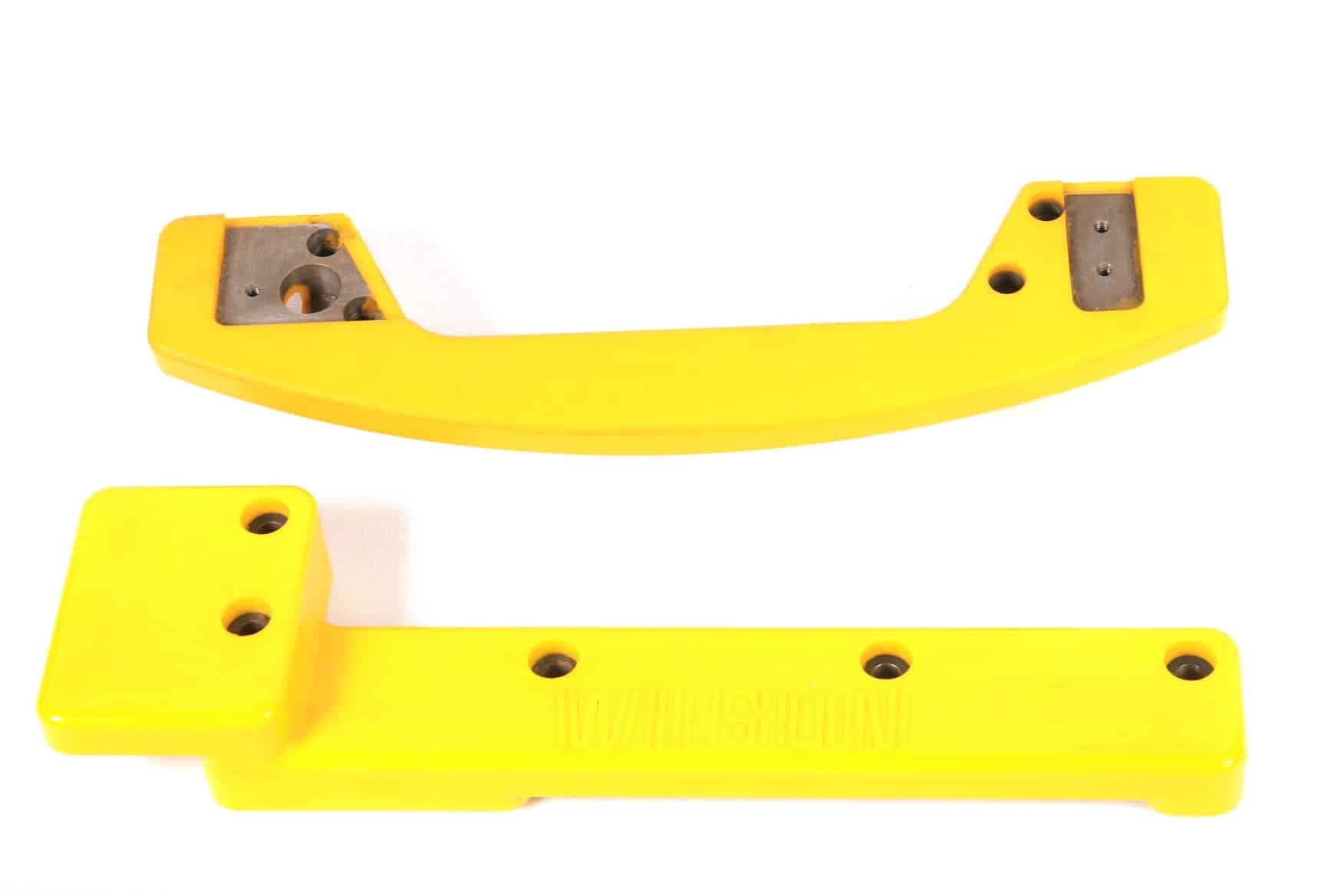

4. Customization for Precision Fit and Enhanced Efficiency

One of the greatest advantages of polyurethane parts is the ability to customize them to exact specifications. Mining equipment comes in various designs, and having components tailored to fit perfectly ensures maximum operational efficiency. From scrapers and conveyor belts to seals and liners, custom urethane parts enhance durability, reduce maintenance costs, and optimize performance across different stages of the mining process.

By integrating custom-made polyurethane components into mining operations, companies can significantly improve equipment longevity, operational efficiency, and cost-effectiveness. Whether for impact resistance, abrasion protection, or precise customization, polyurethane remains the superior choice for mining applications.

👉Also Read: The Versatility of Cast Urethane Products in Various Industries

Applications of Custom-Molded Polyurethane Parts in Mining

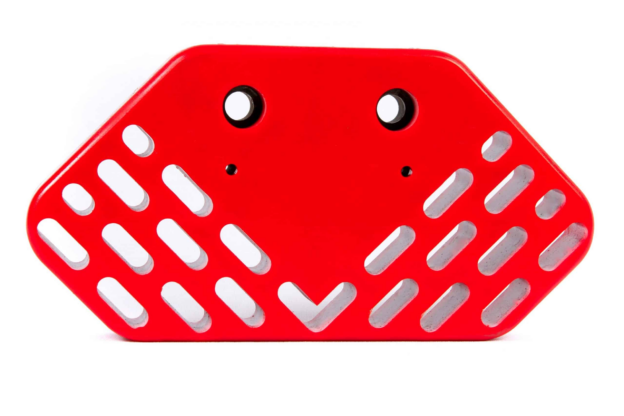

The mining industry extensively utilizes polyurethane products due to their exceptional wear resistance and adaptability to harsh environments. These custom-molded parts are critical at various stages of the mining process, including extraction and processing, where equipment is exposed to abrasive materials and high impacts. Polyurethane liners, impact pads, and seals are particularly valued for their ability to protect equipment and enhance operational efficiency.

Polyurethane parts’ chemical resistant properties prevent degradation when exposed to harsh substances commonly used in mining operations. This ensures that the equipment remains functional and reliable over extended periods.

Custom-molded polyurethane components like conveyor liners, impact pads, and seals are vital for maintaining mining equipment’s efficiency and longevity in various material handling industrial applications. Here are some specific applications:

Conveyor Liners

Polyurethane liners are incredibly effective in protecting conveyor belts, significantly enhancing their durability and performance. Custom polyurethane products can be tailored to meet specific hardness levels, which is essential for various mining applications. This customization ensures that the liners can withstand the specific operational needs and challenges faced in mining, making them an indispensable component of mining equipment.

Impact Pads

Polyurethane impact pads are specifically engineered to endure heavy impacts, contributing to the longevity of mining equipment. These pads are used to absorb shocks and reduce damage to mining equipment, leading to reduced maintenance costs and prolonged equipment lifespan.

This makes polyurethane impact pads a cost-effective solution for enhancing the durability and performance of mining operations.

Seals and Gaskets

Polyurethane seals and gaskets are crucial for preventing leaks, ensuring equipment operates effectively under extreme conditions. These components help to protect the internal parts of machinery from being compromised by maintaining the integrity of the equipment under high pressure and temperature.

Polyurethane seals and gaskets maximize performance, reduce the need for frequent replacements, and promote long-term reliability.

Hydrocyclones and Pump Components

Polyurethane is widely used in hydrocyclones, pump liners, and impellers due to its resistance to wear, corrosion, and chemical degradation. These components play a crucial role in slurry handling and separation processes, where high-impact and abrasive materials can quickly wear out conventional parts. Polyurethane hydrocyclones maintain optimal performance by reducing downtime and increasing equipment longevity, making them an ideal choice for high-intensity mining applications.

Chute and Hopper Liners

Mining chutes and hoppers are constantly exposed to high volumes of abrasive materials, leading to rapid wear and tear. Custom polyurethane liners provide an effective solution by offering exceptional impact and abrasion resistance. These liners not only extend the service life of chutes and hoppers but also minimize material buildup, reducing the risk of clogging and enhancing operational efficiency.

Long-Term Benefits of Precision-Engineered Polyurethane Solutions

Opting for precision-engineered polyurethane solutions offers numerous long-term benefits for mining operations. Polyurethane components help reduce operational costs by minimizing the frequency of replacements, leading to significant cost savings over time. The unique flexibility of polyurethane contributes to its growing popularity in mining machinery, leading to improved operational efficiency and reduced maintenance costs.

Polyurethane coatings provide a protective barrier that resists moisture, chemicals, and UV light, enhancing the longevity of materials. This durability results in fewer replacements and long-term savings, making polyurethane products more cost-effective than traditional materials like metal, plastic, and rubber. Additionally, the ability of polyurethane to reflect infrared heat can reduce cooling costs and enhance energy efficiency.

Bonding polyurethane products to existing components extends the lifespan of mining machinery, contributing to cost savings and operational efficiency. Polyurethane components also enhance safety by reducing the risk of equipment failure, thus preventing accidents in mining environments.

Choosing the Right Polyurethane Manufacturer

Choosing the right polyurethane manufacturer is critical for enhancing the durability and performance of mining equipment. Professionals bring expertise that aids in selecting the right materials and processes for custom-molded urethane parts. Experienced professionals help ensure compliance with industry standards, which is critical for the safety and performance of mining equipment.

Leveraging expertise and ensuring compliance allows mining operations to achieve better-customized polyurethane solutions tailored to their specific needs. Let’s explore the key factors to consider when choosing a polyurethane manufacturer.

Expertise and Experience

At Uniflex, Inc., we take pride in being the leading manufacturer of cast polyurethane products for the mining industry. With years of experience in designing and engineering high-performance polyurethane components, we are committed to delivering durable, custom-made solutions that meet the rigorous demands of mining operations.

Our expertise allows us to develop products that are tailored to the exact specifications of our clients, ensuring superior performance, longevity, and cost-effectiveness. We focus on customer satisfaction by providing innovative solutions that enhance equipment durability, reduce maintenance costs, and improve overall operational efficiency.

Customization Capabilities

Customization is crucial for mining operations as it allows for the adaptation of parts to meet specific requirements and challenges. Non-reinforced urethane liners, for example, can be easily custom-cut to accommodate various specifications of mining equipment.

Effective customization enhances parts’ durability and improves mining operations’ overall efficiency and productivity.

Quality Assurance

Quality assurance is critical in ensuring the durability and performance of polyurethane parts used in mining equipment. Certification for quality management and environmental safety is important for a reliable polyurethane manufacturer. Ensuring that the manufacturing processes meet high standards helps minimize downtime and improve the reliability of the products.

Collaborating with Professionals for Optimal Results

Engaging with seasoned professionals is essential in developing tailored urethane solutions that effectively address the unique challenges faced in mining operations. By collaborating with experts, mining companies can minimize trial and error in the design phase, accelerating the implementation of durable and high-performance polyurethane components.

Working closely with industry professionals ensures that each polyurethane part is precisely engineered to meet the specific demands of mining environments. This strategic collaboration enhances equipment efficiency, extends operational lifespan, and optimizes overall productivity. For mining companies seeking to maximize performance while reducing maintenance costs, partnering with experienced polyurethane manufacturers is a key step toward achieving long-term operational success.

👉Also Read: The Top 4 Industries That Benefit From Custom Polyurethane Products

Partner with Uniflex, Inc. for Custom Urethane Solutions

At Uniflex, Inc., we specialize in designing and manufacturing high-performance custom urethane components in various shapes and sizes to meet the demands of diverse industries, including mining. Our advanced manufacturing capabilities allow us to offer short-run production and prototyping services, ensuring that every project receives the precision and attention it deserves. With tailored mold designs, efficient production processes, and rapid turnaround times, we help our clients optimize performance, extend equipment lifespan, and reduce maintenance costs.

If you’re looking for durable, abrasion-resistant polyurethane solutions to protect your mining equipment, we are here to help. Contact Uniflex, Inc. today to discuss your specific requirements with our team of experts.