Urethane, in its essence, is a polymer with remarkable versatility and dynamic properties. Historically, its discovery has propelled it into various applications, becoming a cornerstone in industries ranging from automotive to construction. Its adaptability makes it a go-to material in the modern world.

👉Also Read: Precision Engineered Conveyor Rollers: The Advantages of Urethane and Polyurethane

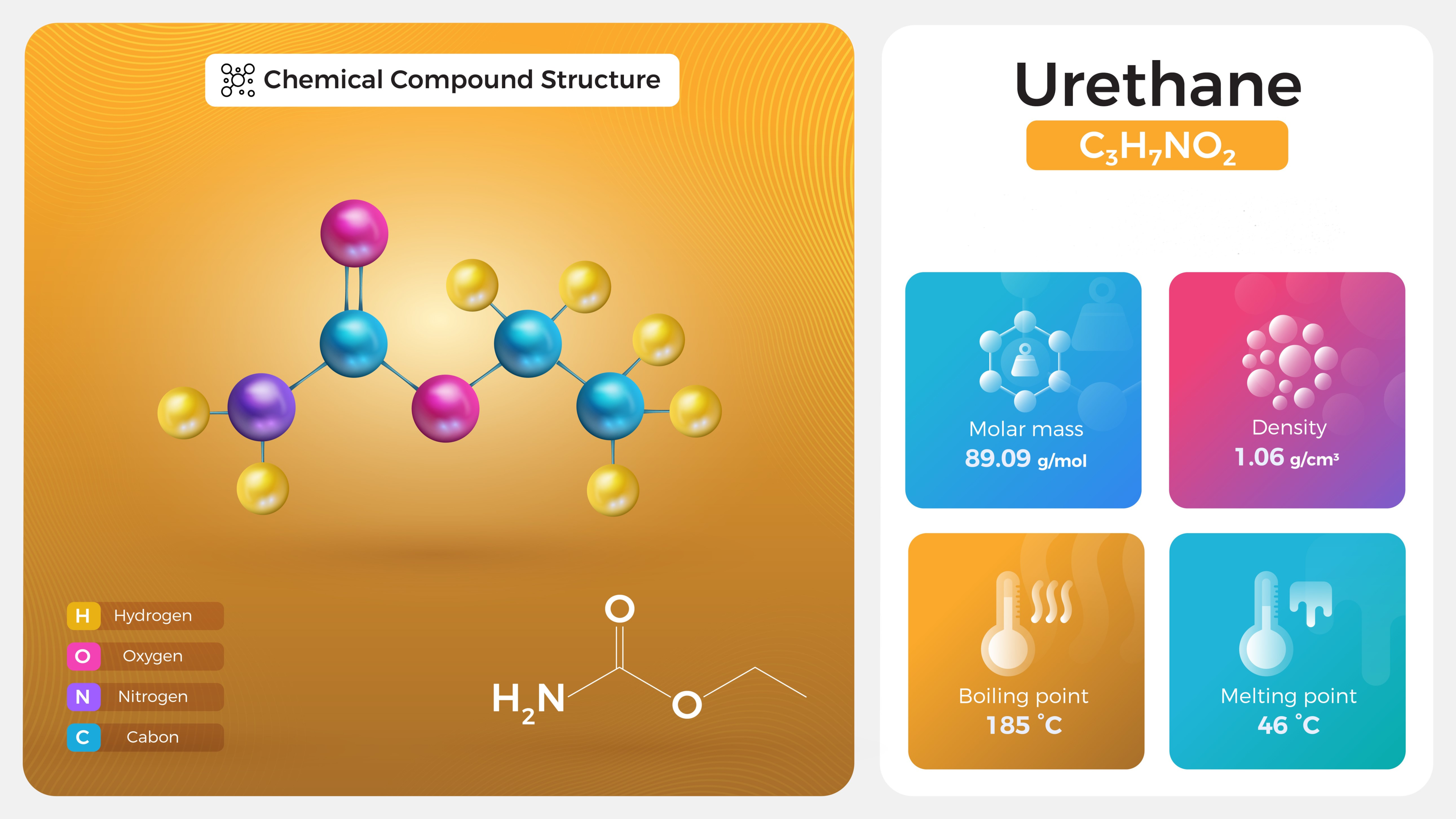

The Chemistry Behind Urethane

Urethane is alternatively referred to as the Ethyl carbamate or Ethylurethane. It stands apart from polyurethanes as an ester of carbamic acid, with its molecular formula denoted as C3H7NO2. Existing in the form of colorless crystals or a white crystalline compound, Urethane, or Ethyl carbamate, is characterized by its lack of odor and a taste reminiscent of saline. Beyond its chemical properties, this compound plays a significant role as an antineoplastic agent and serves as an intermediate in organic synthesis.

Urethane Vs Polyurethane

Urethane and polyurethane are terms used interchangeably! Both refer to various compounds employed for casting, injection molding, or 3D printing custom parts. The interchangeable use of these terms is because polyurethane is a polymer, composed of repeating units chemically linked in a specific pattern, with some of these units being urethane groups. Essentially, polyurethane signifies the presence of multiple urethane groups. This versatile material, including polyurethane elastomers (or urethane elastomers), belongs to the extensive family of elastic polymers known as rubber.

Types of Urethane and Their Applications

Within the diverse family of urethane polymers and derivatives, polyurethane foam emerges as a versatile progeny, claiming its well-deserved spot in an array of everyday items such as mattresses, cushions, and insulation. Its popularity lies in the perfect blend of comfort and insulating properties, providing not just a soft embrace but also efficient thermal regulation.

Moving into the industrial realm, polyurethane coatings step into the spotlight as robust guardians, offering unparalleled protection to surfaces in the automotive and industrial sectors. Their role extends beyond mere shielding; they become a crucial part of enhancing durability and performance in demanding environments.

The adaptability of urethane takes center stage with flexible foam, showcasing its ability to cater to a spectrum of applications. From automotive interiors to packaging materials, flexible foam underscores its versatility, molding itself to the unique needs of each application.

In the manufacturing landscape, urethane casting becomes the maestro, orchestrating the creation of bespoke components with unparalleled precision. This method transforms urethane into a tool for crafting intricate and customized parts, contributing to the efficiency and precision of various industries.

From the soft embrace of foam to the rigid protective armor of coatings, urethane’s prowess is vividly on display, shaping and enhancing products across a multitude of applications. It’s not merely a material; it’s a versatile solution meeting the distinct needs of diverse industries.

Physical Characteristics of Urethane

- Odorless, colorless crystals or white powder characterize urethane initially.

- Easily sublimates at 217°F and 54 mm Hg.

- Exhibits a refreshing saline taste.

- The second type appears as colorless, columnar crystals or white granular powder with a bitter, cold, and saline taste.

- Boiling point ranges from 360 to 363 °F at 760 mm Hg.

- Melting point varies between 118 and 122 degrees Fahrenheit.

- Flashpoint is 198 degrees Fahrenheit.

- Solubility is greater than or equal to 100 mg/mL at 72°F.

- Density measures 0.9862 at 70 degrees Fahrenheit.

Manufacturing and Production of Urethane

Manufacturing urethane is a nuanced art, and the inclusion of chain extenders is a pivotal aspect of crafting urethane compounds. These extenders play a crucial role in dictating the material’s properties and applications, influencing hardness and flexibility.

The diverse manufacturing processes involved, ranging from casting to molding, contribute significantly to the versatility of urethane. Each method ensures that urethane can take on various forms tailored to specific industrial needs.

Rigorous quality control measures are ingrained at every stage of the manufacturing process. This emphasis on quality assurance ensures consistent and reliable performance of urethane products. The material undergoes meticulous scrutiny, with defect prevention mechanisms enhancing its reliability.

This commitment to precision and dependability makes urethane a stalwart choice in industries where stringent standards and consistent performance are paramount.

Urethane in Everyday Life

In the automotive realm, urethane emerges as a silent innovator, significantly enhancing the driving experience by finding application in the creation of car seats. Its role extends beyond the road, playing a pivotal part in the realm of construction materials, where its versatile and durable characteristics shine prominently.

Urethane’s influence, however, is not confined to these visible roles; it quietly operates in the background, contributing to the seamless efficiency of everyday life. From adhesives and sealants to foams, urethane’s unassuming versatility positions it as an unsung hero, subtly elevating various aspects of daily life by making it more comfortable, durable, and efficient.

Environmental and Health Considerations

In the relentless pursuit of modern living comforts, recognizing the dual nature of urethane is crucial. While it undeniably contributes to convenience and innovation, addressing concerns related to toxicity and safety becomes paramount. Taking a closer look at its environmental impact becomes an imperative step in fostering responsible use.

Acknowledging these considerations ensures that the myriad benefits of urethane don’t come at the expense of health or the environment. This prompts a thoughtful exploration of alternatives and the adoption of sustainable practices, aligning industries and consumers toward a balanced approach. In the evolving landscape of chemicals and material usage, urethane becomes not just a symbol of innovation but also a call to balance progress with responsibility.

👉Also Read: Enhancing Durability: How to Get Polyurethane Sheets with Superior Abrasion Resistance

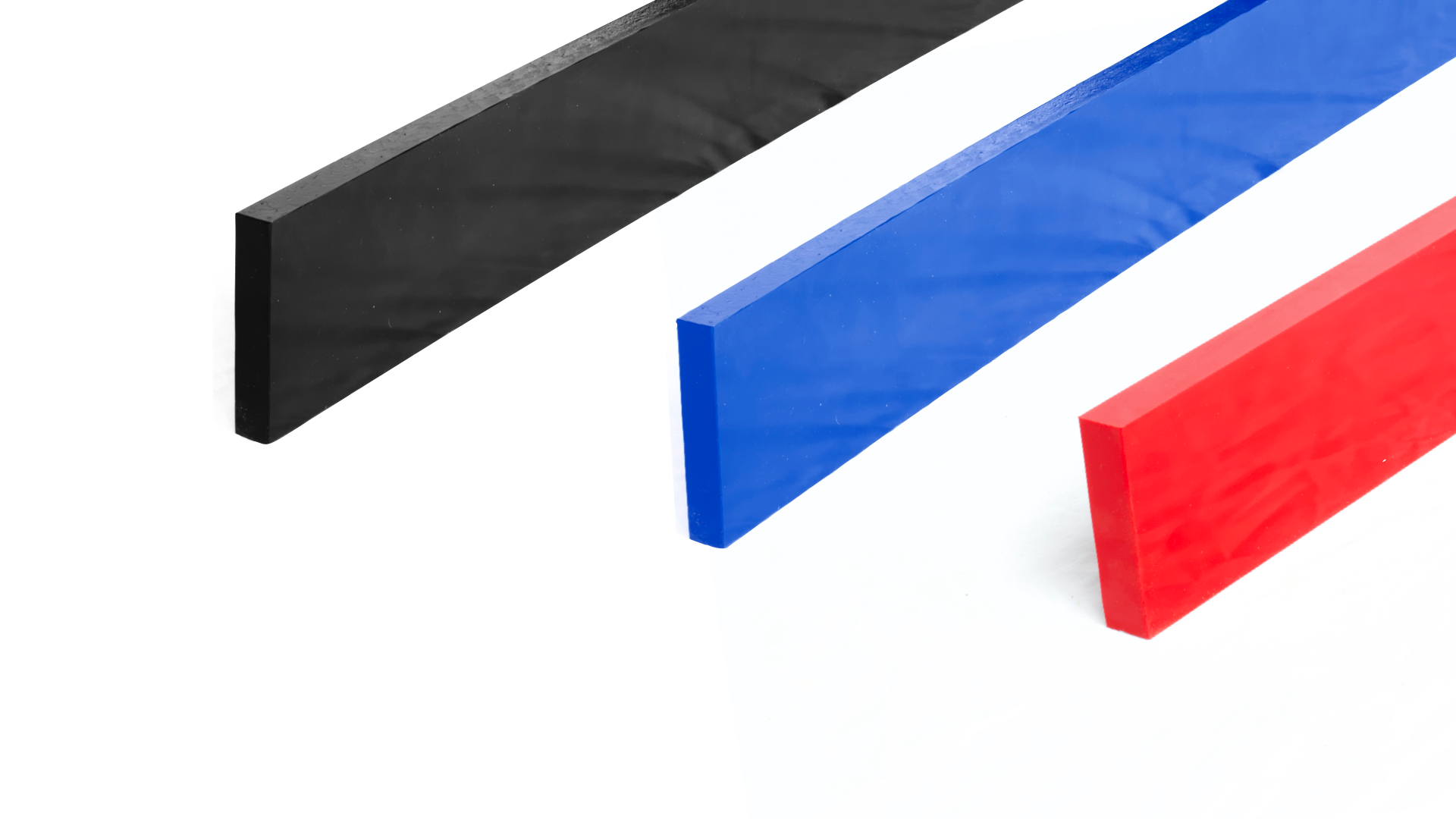

Explore Uniflex, Inc.’s Diverse Polyurethane Solutions for Your Specific Needs

Discover the durability and versatility of Uniflex, Inc.’s high-quality cast polyurethane products, engineered for a diverse range of applications. Our perfected manufacturing processes and proprietary polyurethane formulations ensure the creation of customizable components that can withstand the most challenging environments.

Uniflex, Inc. specializes in polyurethanes designed for high-stress use, offering abrasion resistance, heat tolerance, and unparalleled strength. Our custom molding process allows for infinite customization, reducing production costs and turnaround time.

Explore our extensive range of applications, including food processing, industrial manufacturing, and construction. From custom molded solutions to urethane sheets, bumpers, snow plow blades, pads, rods, and strips, Uniflex, Inc. has the perfect polyurethane product for your needs. Shop our cast polyurethane products now and experience the durability and efficiency that set us apart in the industry!